Issue Date: 28 May 2015

Ref: TAB15/04

Visual Management Goes Modular

Visual management systems are used by manufacturers to convey important information on the shop floor. The best systems present the information simply and effectively. Progressive manufacturers are now taking the concept a stage further by creating visual management installations with the same equipment they use to build production environments to integrate the seamless presentation of vital information.

Visual management is an established technique in many manufacturing businesses. It utilises simple visual signals such as charts, symbols, images and diagrams to convey information rather than relying on cumbersome texts and written instructions. Colour coding is also commonly used. The basic idea behind visual management is that if something is clearly visible it is easier to remember and understand. Presenting everyone in the production area with the same information also helps to support common objectives so they are all focused on the processes and outcomes that are the most important to the success of the business. This methodology shares many goals with lean manufacturing including reduced waste, better efficiency and continuous process improvement.

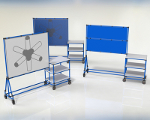

Through its involvement with manufacturers who have embraced lean techniques The Tube & Bracket Company has supported many visual management systems. The company’s modular Graphit and LeanTek ranges of tubes and connectors are widely used to create workstations, production cells and handling equipment in cellular and lean manufacturing environments. The same components are also ideal for creating frames for noticeboards of almost any size. These noticeboards can be built to the size and dimensions required to meet the specific requirement rather than working with off-the-shelf components that might be inefficiently too large or too small. Information is also presented at the right height for maximum impact and comprehension. The components can be reused over and over again to modify or adapt existing installations and maintain their efficiency. Concepts like this are central to the whole lean manufacturing approach.

The adaptability and flexibility of the Graphit and LeanTek components means users are no longer constrained to two-dimensional visual management systems. Instead, noticeboards can be integrated into any structure used within a lean manufacturing environment such as a workstation, production cell or line-side racking. This ensures that visual information is presented to operators seamlessly within the working area.

A modular approach also allows users to devise and configure a whole range of innovative three-dimensional structures to present their visual information. This can include, for example, walls or gantries positioned at the entrance or exit of a working area so that employees see the information as they arrive or leave. Items such as lighting, video screens and other audio-visual equipment can all be incorporated into the structures to enable the creation of integrated solutions that are visually impressive while still maintaining the clean lines and simple design that are the hallmarks of an effective lean manufacturing solution.

The Tube & Bracket Company recently created a set of installations like these for a major manufacturer where they are positioned at the entrance to production lines as a “centre of excellence” to convey vital production, waste reduction and safety information. The structures are built using stainless steel tubes and brackets with bespoke whiteboards which also incorporate clear pockets for the easy insertion of printed notices such as performance charts. Permanent signage and corporate branding has been printed onto boards which top each column of the structure. The company has also supplied a number of production area handling structures for the same customer. This means that the production and visual management systems have a consistency which helps give the area a modern, integrated and well-designed appearance.

The visual management system is used to present employees with concise information about the performance of the production area. This includes details of production volumes, the status of projects, performance against goals or targets, calls to action, and safety information. As with all visual management systems the objective is to be as clear and unambiguous as possible by presenting relevant information in the simplest possible way and removing anything that is irrelevant or not geared toward the improved efficiency and effectiveness of production processes. In this way it provides rapid and readily understood feedback to employees so that they are able to respond quickly to changing business requirements.