Issue Date: 7 December 2015

Ref: TAB15/05

Britax PMG Cuts Production Area By Three Quarters

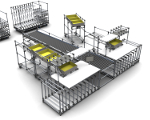

Vehicle lighting manufacturer Britax PMG has reduced the footprint of a major assembly area at its factory by 75 per cent following the introduction of lean manufacturing equipment supplied by The Tube & Bracket Company. New workstations created using modular components have replaced conventional benches as part of a continuous improvement programme to streamline production operations.

Part of the international Ecco Safety Group (ESG), Britax PMG manufactures a wide range of mandatory and auxiliary lighting and complementary products for use by original equipment manufacturers and commercial vehicle aftermarket customers. The company has grown significantly and wanted to enhance the efficiency and productivity of a key production area to meet increased demand. The continuous improvement team was familiar with lean manufacturing principles and approached The Tube & Bracket Company for assistance.

The existing production area had ageing workbenches that were large and cumbersome. They incorporated too many services, tools and equipment that were no longer needed. Britax PMG recognised that new workstations that could be optimised for efficient production and reconfigured when processes changed would meet its needs far better.

The two companies devised a new workstation built from modular components. They used a process known as spaghetti mapping to identify all of the movements involved in the manufacturing process including the handling of assemblies, components and tools. This led to a design for the ideal workstation layout. Tubular steel components of varying lengths were then joined using steel brackets to create the basic workstation frame to the precise dimensions identified during the analysis. A bench, wheels, power sockets, lighting and tools including a soldering gun were added to the frame to complete the workstation.

The size and shape of each workstation is optimised for the particular production process for which it is used. They are just the right size, neither too large or too small. This has helped reduce the size of the production area from 133m2 to 33m2, equivalent to saving 75 per cent of the available space.

Every item has its place on the workstation which helps operatives to maintain a clear and uncluttered working environment but also helps them to identify the correct tool and component. Everything is within easy reach for efficient and ergonomic working. All of the modular components are reusable which means that structures can be modified whenever the application requirement changes or when small incremental process improvements are identified. This ability to adapt and evolve is central to the lean manufacturing concept.

Components for lighting products are supplied to the workstation in the correct sequence and position for efficient and ergonomic assembly using live racking fed from outside the production area using a highly efficient Kanban process. This eliminates the need for stock control operatives to enter production areas so that maximum efficiency is maintained at all times. Extensive colour coding has been introduced throughout the production area to help staff identify the correct position for the workstations, handling and storage equipment, and even individual items. Cushion flooring installed throughout the reconfigured area has reduced fatigue for staff who spend a lot of time on their feet.

The Tube & Bracket Company assembled the workstations and other handling equipment at its factory in Banbury before delivering them to Bridlington. The initial reconfiguration of the factory resulted in around half of the site being converted to the new lean manufacturing operation. Britax PMG is currently rolling the concept out across the rest of the site.